Concrete is the world’s most used building material, yet maintenance and cracking are perennial issues. Imagine if roads, bridges, and buildings could repair themselves — autonomously. That’s the promise of self-healing concrete, often powered by bacteria, microcapsules, or smart materials. This technology offers sustainability, cost savings, and safer infrastructure.

Mechanisms Behind Self-Healing Concrete

There are several strategies:

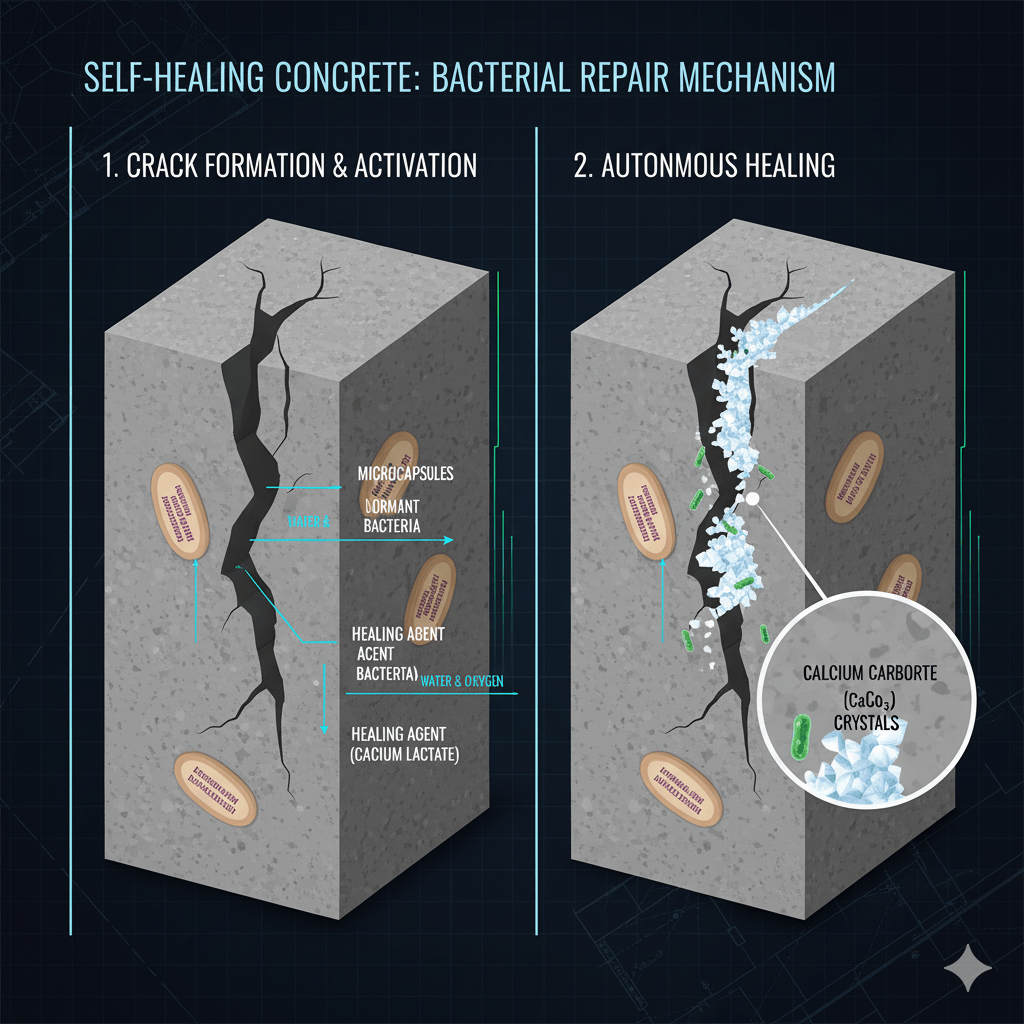

- Bacteria-based (bio-concrete): Dormant bacteria (like Bacillus species) embedded in concrete activate when cracks allow water and oxygen to enter. These bacteria metabolize nutrients and precipitate calcium carbonate (CaCO₃), filling cracks.

- Microcapsules or vascular networks: Capsules containing healing agents (epoxy, minerals) break open when cracks form, releasing the agent to seal the crack.

- Intrinsic crack closure / autogenous healing: Uses concrete’s natural tendency (unhydrated cement particles or carbonation) to self-seal very fine cracks over time under ideal conditions.

- Smart additives / polymers: Shape-memory polymers, gel-forming agents, or stimuli-responsive compounds help close cracks actively.

In bacterially mediated healing, when water enters the crack, bacteria produce CaCO₃ crystals that precipitate and fill voids.

A graphical illustration shows microcapsule self-repairing in cement-based materials.

Recent Research & Developments

- A systematic review highlights that bacteria can reliably seal micro-cracks, but maintaining bacterial viability inside harsh concrete is challenging.

- A study in Nature modeled how bacteria concentration affects mechanical performance and crack healing.

- The Advances in Materials review outlines design approaches for self-healing polymers, which may integrate with concrete-like composites.

- Engineering firms (e.g. Basilisk) have commercialized self-healing concrete using limestone-producing bacteria that activate on crack formation.

- Research from Drexel University explores structural “veins” of bacteria that could form internal healing networks.

Advantages & Why It Matters

- Reduced maintenance cost: Fewer repairs, longer infrastructure life, less spending on patchwork.

- Safety & durability: Cracks can allow water, chemicals, and freeze-thaw cycles. Healing them prevents deeper structural degradation.

- Sustainability: Fewer repair materials, less demolition, lower carbon footprint.

- Resilience: Infrastructure that heals itself is more resilient to stress, natural events, and aging.

Challenges & Limitations

- Viability of bacteria & longevity: Bacteria must survive the high alkalinity, pressure, and limited nutrients inside concrete.

- Scale & crack size limit: Self-healing is more effective for micro-cracks. Larger structural cracks may need manual repair.

- Cost & manufacturing: Embedding capsules or bacteria raises cost and complexity.

- Environmental constraints: Healing often needs water, oxygen, or controlled conditions. In dry or saturated environments, effectiveness may drop.

- Performance tradeoffs: Adding capsules or bacteria may affect original concrete strength, porosity, or durability if not optimized.

Use Cases & Applications

- Bridges and overpasses: Where crack propagation is critical.

- Tunnels, dams, and water tanks: Because leaks or cracks can be catastrophic.

- Pavement & roads: Micro-crack healing can delay large-scale resurfacing.

- Buildings in harsh climates: Self-healing helps resist freeze-thaw cycles, corrosion, and aging.

- Marine, offshore structures: Resistant to saltwater infiltration when cracks form.

One published review notes that successful self-healing requires balancing bacterial pathways, encapsulation techniques, concentration, temperature, and pH.

Another review says self-healing bioconcrete is an “emerging field aimed at extending concrete lifespan and reducing repair needs.”

Future Directions & Outlook

To advance, research is focusing on:

- Better bacterial strains and encapsulation: More robust, long-living bacteria or spores resistant to concrete conditions.

- Smart networks: Vascular microchannels inside concrete to deliver healing agents where needed.

- Stimulus-responsive healing: Using triggers (e.g. pH, moisture, electric field) to activate healing on demand.

- Integration with sensors & IoT: Concrete that senses crack formation and triggers repair.

- Cost reduction & scale-up: Making embedding techniques scalable, and cost-effective for large structures.

If these challenges are resolved, self-healing concrete could become a standard in civil engineering, greatly reducing lifecycle costs and improving infrastructure resilience.